Pre-sand blanks or refine scrolled projects without breaking a sweat

By Carole Rothman

When you consider how many different types of sanders have the word “drum” in their name, you can appreciate how confusing the terminology can be, for both novice and experienced woodworkers. Even if you know this tool well, the ways in which it translates to scrolling might not be immediately clear. In this article, I’ll break down the basics: what a drum sander is, how to use it, and what to look for if you choose to add one to your shop. Then once you are comfortable with the drum sander, try it out on one of our fall projects.

| If one face of the stock is uneven, as may occur in blanks with glued-in components, that face should be sanded first. Sanding is complete when you reach the desired thickness, and both surfaces are parallel, smooth, and free of irregularities. |

36-, 60-, and 100-grit wraps. |

Use a Drum Sander To…Prepare a figured wood blank for scrolling.

|

Apply double-sided tape to stabilize a twisted board.

|

|

Smooth surfaces on marquetry.

|

Sand cupped wood convex-side up.

|

Uses in ScrollingDrum sanders are typically used for stock preparation, and not for finishing work. However, by using a higher grit wrap such as 220, you can easily and efficiently create a finished surface on your wood before it is cut. This is especially useful for delicate fretwork projects, whose thin bridges are vulnerable to breakage, and also for large blanks that are to be cut into smaller pieces. You can also use the drum sander to level the surface of an inlay, or give a smooth finish to a puzzle, provided that the puzzle pieces have been secured so that no movement occurs when they are passed under the drum. |

Drum Sanders vs. PlanersIf you have a planer, do you need a drum sander? Despite some overlap in function, there are significant differences between the two. Planers reduce stock more efficiently than drum sanders. However, damage to the wood, such as tear-out, can occur if the cutters are dull, or if the wood is highly figured or planed against the grain. Drum sanders remove stock at a slower pace, even when coarse grits like 36 or 60 are used. The sanding action is gentle and can safely be done with or against the grain, making it the tool of choice for wood with irregular grain patterns and fragile items like thin wood or marquetry. |

Open-end drum sander. |

| Both planers and drum sanders require that the workpiece sit flat when passed through the machine; any deviations will be transferred to the parallel upper face. This creates problems if the wood is twisted, cupped, or bowed.

While you can use a jointer or hand plane to flatten the bottom face, the conveyor belt of the drum sander permits a simpler solution. For twisted wood, I attach pieces of thick double-sided tape under the raised corners to create a stable base. I then sand the wood, tape-side-down, as I would any other board. The early passes remove only the high spots; the sanding sound is intermittent and distinctive. This sound becomes more regular as the high areas are removed and more of the upper surface can be sanded. A continuous sound throughout the pass signals that sanding is at or near completion. When the sanded surface is flat, I remove the tape, and repeat the process for the remaining face. Cupped or bowed wood thick enough to resist the drum’s downward pressure can be passed through the sander with the convex side up, with tape added to the bottom corners to correct any twist. The finished, flattened stock will be thinner than before, but is no longer firewood! |

|

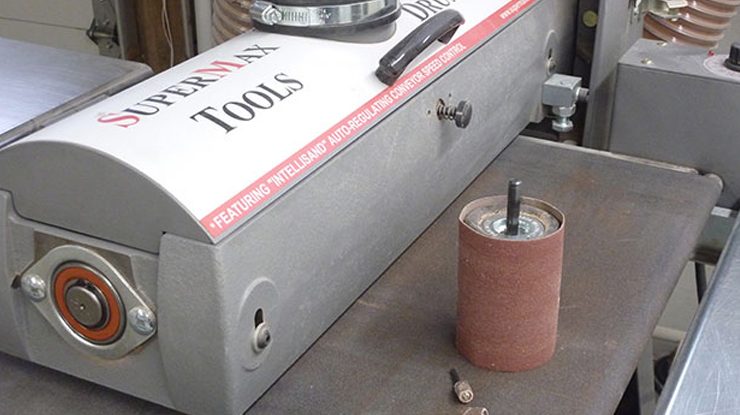

Drum sanders also vary in the maximum stock thickness they can handle; 3″ (7.6cm) and 4″ (10.2cm) limits are typical. Most can sand stock down to 1/32″ (1mm), perfect for making veneer from resawn wood, and most can pass pieces as short as 2 3/8″ (6cm) through the drum. Infeed and outfeed tables, available as options, facilitate the feeding of long boards and help prevent gouging at their ends. If shop space is limited, look for models with tables that fold down when not in use. If you’re likely to sand both thick and thin wood, a sander with a quick-adjust lever that rapidly raises or lowers the height of the drum can be a real time and wrist saver; if precision is critical, consider a model with an integrated digital readout. And, if you anticipate sanding with several different grits, be sure that the clamps that secure the ends of the wrap are easy to use. This makes changing the wrap quick and easy for hands of every size and strength level. A well-designed sander should be easy to maintain, with components that are accessible if adjustment or repair is needed. Tech support staff should be knowledgeable and replacement parts readily available. |

Drum sander clamp for abrasive wraps. |

ConclusionMy experience with the less satisfactory drum sanders of the past has helped me appreciate the quality of those currently available. Aside from my scroll saw, my drum sander is among the most valuable and frequently used tools in my shop. |

| About the Author |

| Carole Rothman of Pawling, N.Y., is a retired psychologist and college professor. She is also an award-winning cake decorator. Visit Carole online at scrollsawbowls.blogspot.com. You’ll find her books, Creative Wooden Boxes from the Scroll Saw and Scroll Saw Wooden Bowls: Revised & Expanded Edition, at foxchapelpublishing.com. |

|

Purchase our fall issue!

Purchase Our Fall Issue Here!

For more articles like these, subscribe to Scroll Saw Woodworking & Crafts magazine. SubscribePlus! Get mini magazines in your e-mail between printed issues with Short Cuts, our e-mail newsletter. |