Here are a few words of wisdom to make your next scrolling adventure or pattern project a safe and enjoyable one!

By Rick Hutcheson

Note: This article originally appeared in our Spring 2001 Issue (#2).

We buckle our seat belts. We’re constantly reminding our children or grandchildren to wear their helmets when cycling, scootering or skateboarding. But, when we see the rather benign-looking scroll saw, we furrow our brow and ask ourselves, “Shucks! How can a teeny weeny blade like that hurt anyone?” For the most part, we are correct in assuming that the scroll saw is a relatively safe tool, but blades break, blade clamps grow wings, foot pedals get stepped on, and sawdust gets everywhere. Everyone assumes woodworking accidents only happen to the other guy—but we are all someone else’s “other guy.”

The following is a look at some of the safety issues involved with scroll sawing and how you can be a more safety-conscious woodworker.

Don’t be a Hero:

Scroll saw safety savvy starts from the moment you open the box and lift the saw. It’s heavy, so you may need to get some help when setting it up right out of the box. Folks, save your back, and don’t try to be a hero, please!

The saw is somewhat of a portable power tool, but is best used as a stationary device. The saw can be attached to your workbench, but this mounting method usually increases the saw’s vibration.

Having all the weight at the top of the stand makes the saw top heavy. So, it can easily be tipped over if not mounted properly. Regardless of which stand that you mount the saw on, make sure that the saw is stable. The best safety-related mounting advice is to use the stand for that saw. What’s more, a 3-legged stand will sit more firmly and vibrate less.

Jeepers, Creepers, Protect Those Peepers:

If you have ever been around a scroll saw when a blade breaks, the need for eye protection becomes rather obvious. When those small blades fail, they sometimes break into many small pieces. We have no way of controlling where they go or what body part they land on. On some saws with removable blade clamps I have had clamps loosen and fly off into the great unknown. We only have one set of eyes and to lose either one of them could be a major disaster. Before we even turn the saw on, we ned to protect our eyes.

Standard spectacles are no substitute for protective eyewear. Case in point: I wear prescription glasses with safety lenses so my eyes are protected all of the time in the shop. There are many types of safety glasses, goggles, and face shields on the market to protect your peepers. It’s a matter of personal choice and what style you feel the most comfortable wearing. But, whatever type you choose, make sure to wear something.

Doing the Foot-Pedal Shuffle:

After set up, the saw is probably going to be plugged into a 110-volt-alternating current grounded outlet, that is, unless your machine is treadle-, solar-, or thought-powered.

Foot switches, or pedals, are a great tool to help us concentrate on the business of scrolling. However, we can be so focused on proper blade installation or some other part of the project that we may find ourselves stepping around the side of the saw and BANG-we just stepped on the foot switch and energized the saw. Not a very safe practice indeed. Had we unplugged the saw before changing the blade, this accident could have been avoided.

For safety’s sake, unplug the saw whenever you change the blade or make adjustments to the saw table, even if you have a foot pedal. This is a good habit to get into to ensure that the saw does not start when you have your hands and fingers around the arms and blade clamps.

Music to Your Ears:

Some saws are very quiet when running by themselves, but become louder during cutting. Then there are saws that are noisy to start with. And some scrollers will use a shop vacuum as a dust collection system to boot. When you add up all these decibels, it’s easy to see that some type of hearing protection may be in order when scrolling.

Sponge-type earplugs are the cheapest way to go. Then there are so many levels of the ear-muff-style hearing protection that I could never describe them all. This type of hearing protection ranges from styles that partially block sounds, to types that will block almost all sound. Choose a style that gives you the most protection and that you’re most comfortable with. You can elect to purchase custom-molded earplugs, but these need to be fitted by a doctor.

Some scrollers choose to use stereo headphones so they can listen to music while they saw. I don’t condone this practice–you can become too involved in the music and lose concentration on the sawing that your hands are doing. When scrolling, you need to concentrate on the saw just as you would with any other power tool. Accidents can happen anytime, and they can happen fast.

Waiting to Inhale:

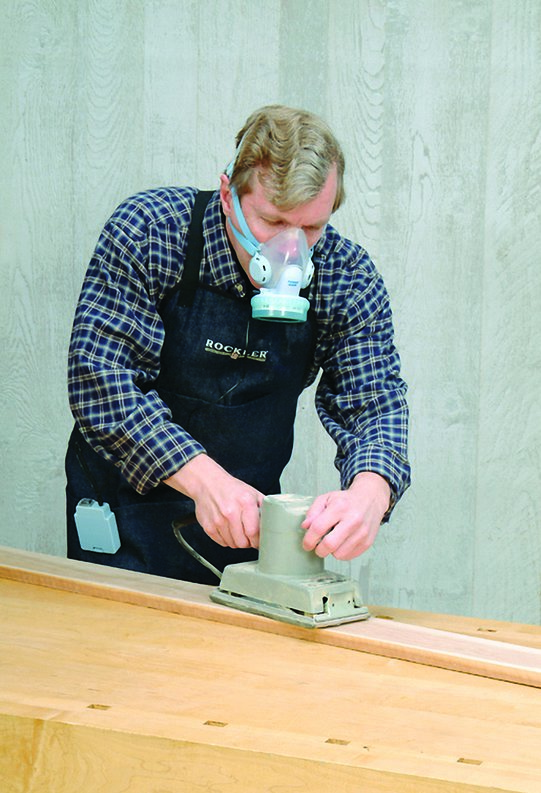

We often forget that scroll saws use a very fine blade with very fine teeth, which generates fine particles. The scroll saw doesn’t make a whole lot of dust when compared to other woodcutting tools. But, whether it’s Birch, Paduak or Purple Heart, airborne dust can have adverse breathing effects. Even garden-variety pine dust can create respiratory irritation.

If you cut for awhile you never see much sawdust. But wipe your hand across things in the area you were cutting in, and you’ll find that a very fine layer of dust has coated everything. The dust was in the air you were breathing before it settled. Some exotics can be more harmful than others, but all dust particles can work their way into your lungs and with time can cause problems.

So wear a dust mask, or control the airborne dust with other suitable methods. The cheap mask filters may work fine for most of your general cutting. But when cutting some of the more toxic, exotic woods you may want to acquire a better grade of air filtering mask.

Air filtration systems are another way to control dust. There are commercial ones available that do a great job. You can eve build your own from a furnace blower, like I did in my shop. With the proper filters these can be just as effective as the commercial ones. It’s been my experience that air filtration units work best when mounted above and behind the saw so the dust is pulled away from you when you’re cutting. My homemade “blower box” vents right into the room, which circulates the air nicely to boot.

Clamping Down:

The most visible scroll saw safety feature is the hold-down clamp. My guess is that 75% of scrollers have removed the hold-down because it always seems to be in the way. The Federal government mandates the clamp. Therefore, it should be used at all times for safety’s sake. When properly used, the lamp holds the wood to the table and blocks most of the path to the blade.

The lower blade guard is another safety feature that sometimes gets moved, or removed. On some models there’s a guard in place around the lower blade clamp to protect your fingers from getting between the arm and the bottom of the table. zSometimes this guard can be moved aside to gain access to the blade clamp. Please don’t remove these guards-the fine folks at the factory put them there for a reason, and they should be left in place.

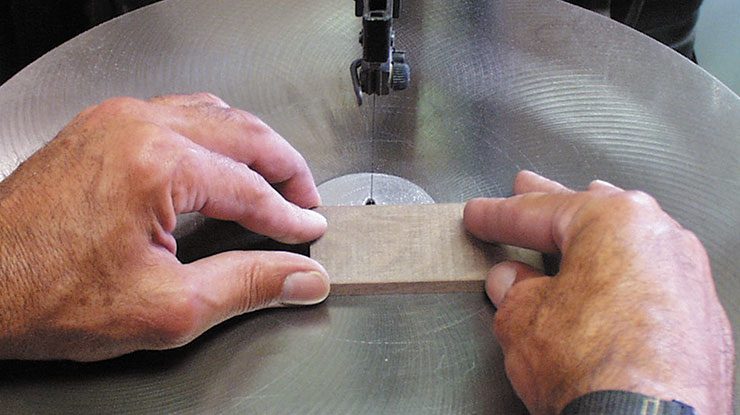

Regardless of which type of safety device you may, or may not, have, keep your fingers off to the sides of the blade and do not place fingers in front of the blade path. Especially when scrolling narrow strips, because the blade can jump out of the cut and you might push your fingers into the blade before your reflexes take over.

When cutting very small pieces of wood, use a cardboard backing to help control the wood and keep your fingers out of the blade’s path.

Better Safe Than Sorry:

It’s important to develop good safety practices any time you are using any type of woodworking machinery or hand tool.

Please make safety glasses and hearing protection standard procedure. Be sure to read and follow the manufacturer’s recommendations for power-tool safety. Read and follow the safety recommendations for the use of finishes (good ventilation and lots of it).

Some say, “discretion is the better part of valor.” When it comes to shop safety, that cliche could not be truer. Don’t overdo it: if you feel yourself getting tired, take a break. Most accidents in the shop happen when the woodworker is tired or when his or her attention is focused elsewhere.

It’s tempting to ignore shop safety practices and not to wear protective equipment, but it’s better to be safe than sorry. Besides, as scroll saw mentors we have to set the example for others and also for the younger folks. In closing, scroll saw safety isn’t rocket science-it’s just good common sense!