Always pick the right blade for your project

Choosing the Right Teeth

Use skip tooth blades when you need a fast cut and are not concerned about splintering on the bottom. Use reverse-tooth blades when you need a relatively fast cut that leaves a smoother surface on the bottom. Use double-tooth blades when you need a smooth cut and aren’t concerned about speed. Use spiral blades when you need to cut in various directions without turning the wood.

Broken Blades

The main reason blades break is improper tension. Too little tension allows the blade to bend and too much tension stretches the blade. Test the tension by the sound the blade makes when you pluck it. Strive for a high C tone. A properly tensioned blade will not move more than 1/8″ in any direction.

Blades also break because too much pressure is applied when cutting. This causes the blade to overheat or bend. Use caution to avoid bending the blade when feeding it through tiny blade-entry holes.

Reverse-Tooth Blades

According to Chuck Olson of the Olson Saw Company, the reverse-tooth scroll saw blade was first developed by Olson in the late 1950s for Playskool. Playskool was stack cutting 10 puzzles from 1/8″-thick wood, and had to throw away the bottom puzzle because of tear out. Reverse-tooth blades prevented this and increased productivity. Olson introduced the reverse-tooth scroll saw blade to the general public in the early 1980s.

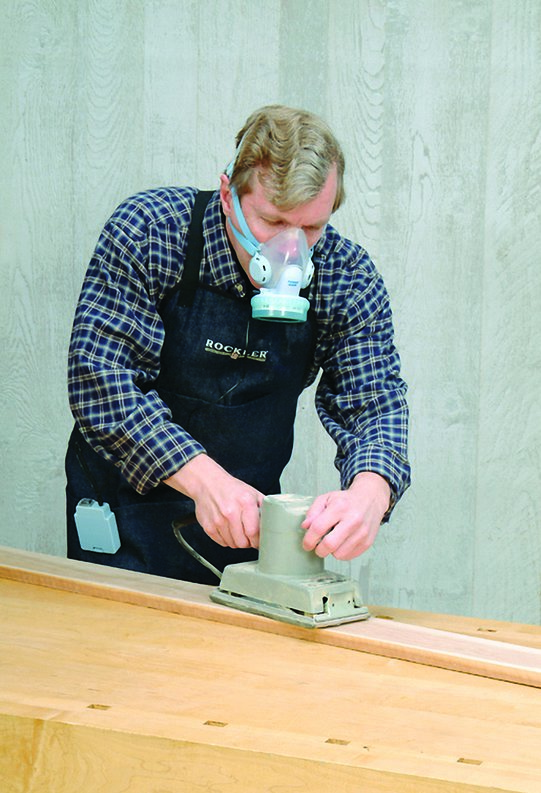

Lubricating the Blade

To increase blade efficiency and prevent scorching of the wood, many scrollers use tape on their workpiece. Mike Moorlach, owner of Flying Dutchman Blades, determined that it’s actually the chemical that manufacturers use that acts as a lubricant. The chemical keeps the tape from sticking to itself on the roll. All tape has this property, so it doesn’t matter if you choose masking tape or clear packaging tape.

Top Feeding vs. Bottom Feeding

To feed from the bottom, release the blade from the top blade holder, lift the workpiece, thread the blade up through the next blade-entry hole, and reattach the blade at the top. To top feed, you need a saw that has a pivoting upper arm. Remove the blade from the bottom blade holder, lift the upper arm, move the workpiece and thread the blade back down through the next blade-entry hole. Re-clamping the blade in the bottom blade holder does take a bit of practice, but many scrollers find it easier, and faster, to locate the blade-entry hole from the pattern side of the workpiece.

Over or Under

Some scrollers attach the pattern to the wood, then cover the pattern with clear packaging tape. This helps keep the pattern attached to the wood, but sawdust can collect between the pattern and the tape, obscuring the lines. Other scrollers put the tape directly on the wood, apply spray adhesive to the pattern, and position the pattern on top of the tape. It’s a good idea to use colored masking tape with this method. The bright colors make it easy to spot any missed tape, and the colored painters’ tape is easier to remove than traditional masking tape.

Discuss this material on the Scroll Saw Woodworking & Crafts forums.